Beneficiation Group

Source file: 6. Beneficiation Group.htm

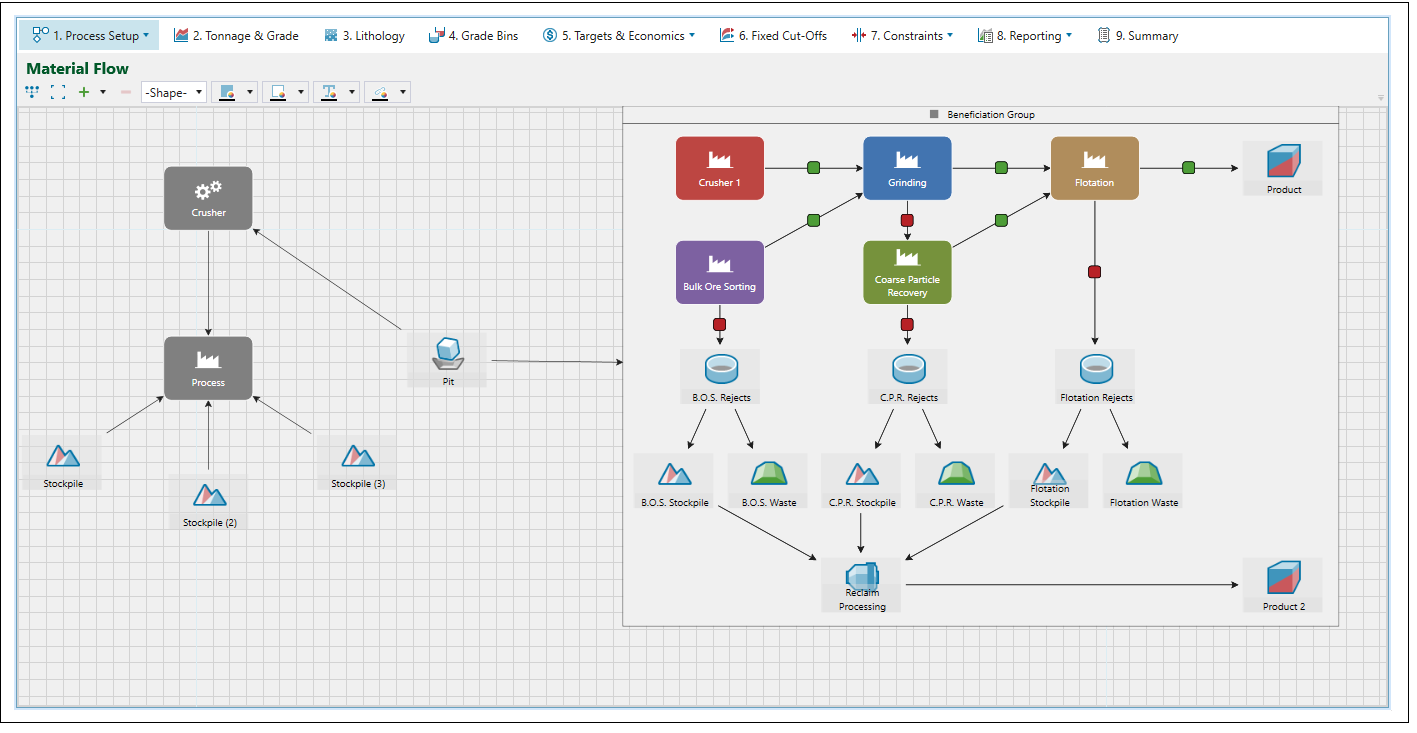

Beneficiation flowchart

A beneficiation group is a special kind of process node that can be added to the flowchart. The group accepts ore directly from pits and stockpiles and is used to calculate the saleable product and revenue produced in the schedule. Beneficiation groups in Strategy streamline the handling of the obtained ore material, and help to manage the waste tailings, which also result from the beneficiation process.

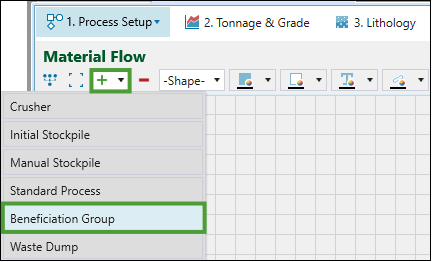

To add a beneficiation group to your setup, go to ![]() Process Setup tab >

Process Setup tab > ![]() Material Flow subtab and click the

Material Flow subtab and click the ![]() button. Select Beneficiation Group from the drop-down menu.

button. Select Beneficiation Group from the drop-down menu.

A beneficiation group will be added to the flowchart.

Tip: You can customise the colours and shapes of process nodes within the beneficiation group the same way as in the case of standard process nodes in your setup. See Material Flow toolbar for more information and examples.

Note: Only pits and stockpiles can be linked to the beneficiation group.

Unlike a standard process, the beneficiation group can simulate various subprocesses within a processing plant. These subprocesses are:

-

- Crusher

-

- Bulk Ore Sorting

-

- Grinding

-

- Coarse Particle Recovery

-

- Flotation

Material flowing into the beneficiation group (feed) is split between the Crusher and Bulk Ore Sorting processes. Material exiting the group is considered a saleable product, and generates revenue for the operation.

Note: The current layout of the beneficiation group is fixed and does not allow for alterations, so it may not be applicable to all mine sites.

According to the example flowchart in the image above, the material taken directly from the pit or from a stockpile is sent to the crusher or bulk ore sorting, depending on which type of processing is needed. The amount of material that is sent for further processing (indicated by ![]() icons in the flowchart), and the amount of material that is sent for further recovery, sorting, or to the waste dumps (indicated by

icons in the flowchart), and the amount of material that is sent for further recovery, sorting, or to the waste dumps (indicated by ![]() icons in the flowchart) correspond to the specified mass pull factor.

icons in the flowchart) correspond to the specified mass pull factor.

The product output of the flotation process is used to calculate the revenue for the process. Rejects from the bulk ore sorting, coarse particle recovery and flotation processes can either be sent to waste, or reclaimed via stockpile by the reclaim process. This process also generates revenue.

The group’s waste dumps cannot share capacity with each other, or with dumps external to the group. Similarly, the internal stockpiles are all separate.

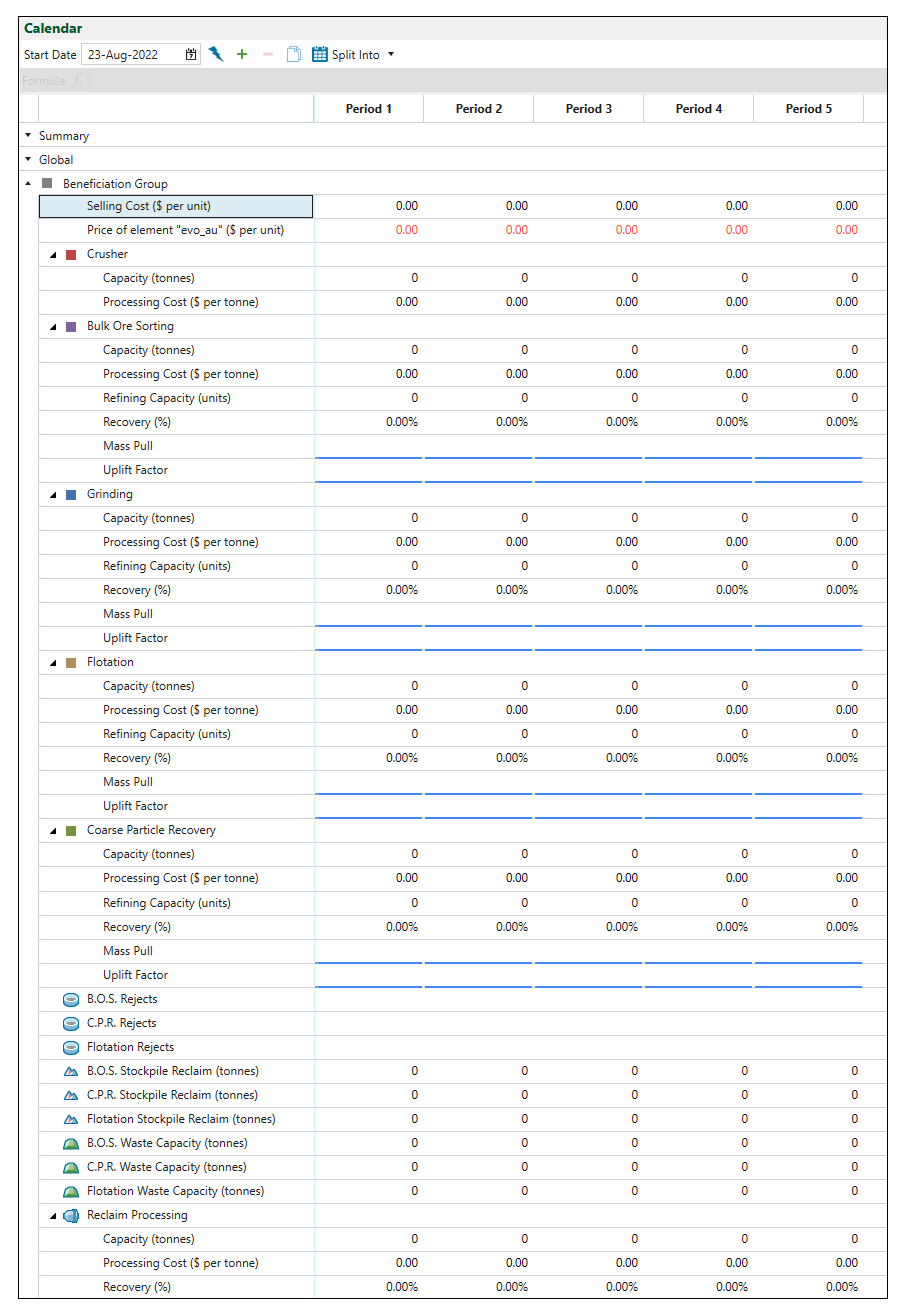

All operating parameters for the group, such as mass pull, uplift, recovery and material splits are set under the ![]() Targets & Economics tab in the

Targets & Economics tab in the ![]() Calendar. For more information, see the Configuration part below.

Calendar. For more information, see the Configuration part below.

Configuration

To configure your beneficiation group, go to the ![]() Targets & Economics tab and enter the

Targets & Economics tab and enter the ![]() Calendar subtab. You can specify the capacity, costs, and criteria for each process per period by entering the values manually. For the Mass Pull and Uplift Factor, you can either enter the values directly or you can apply a formula that will calculate the values based on the input variables you provide. If you apply a formula, it will define the way the material is split between these processes.

Calendar subtab. You can specify the capacity, costs, and criteria for each process per period by entering the values manually. For the Mass Pull and Uplift Factor, you can either enter the values directly or you can apply a formula that will calculate the values based on the input variables you provide. If you apply a formula, it will define the way the material is split between these processes.

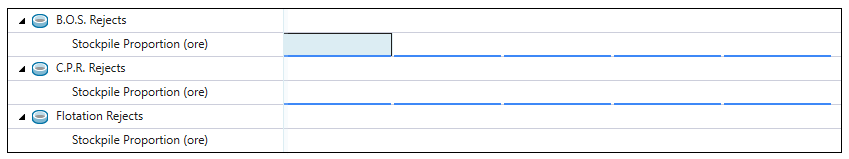

The ![]() Calendar subtab also allows you to set the ratio of the material to be sent for processing and to waste from the connected source (pit, stockpile, or both).

Calendar subtab also allows you to set the ratio of the material to be sent for processing and to waste from the connected source (pit, stockpile, or both).

To specify the split ratio, in the Stockpile Proportion row, enter the proportion (in decimal form) of the material that should be processed further. The remaining part of the material will be sent to waste by default. You can designate the destination proportion for all the nodes that split the material between the stockpiles and waste dumps.

Note: You can also enter a formula so that the stockpile proportion can be calculated automatically.

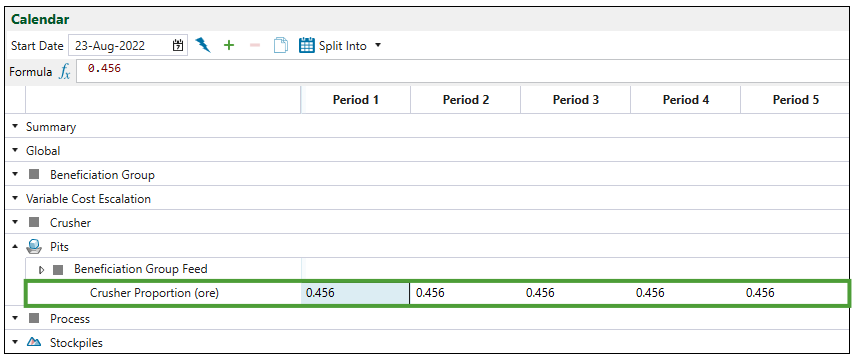

You can also specify the ratio of the mined material to be sent to the crusher within the beneficiation group. To do so, enter the required value (either manually or by inserting a formula) in the Crusher Proportion row under the Pits category in the calendar. The rest of the material will be automatically sent to bulk ore sorting.

Note: If there is more than one beneficiation group in your setup, you can set different crusher proportion values for each group.

Note: These settings are currently applicable to stockpile groups and pit groups. For example, if there is more than one pit in your setup, the overall amount of the material mined from the pits linked to a beneficiation group will be split and sent to the crusher and bulk ore sorting according to the specified proportions.

Lithology

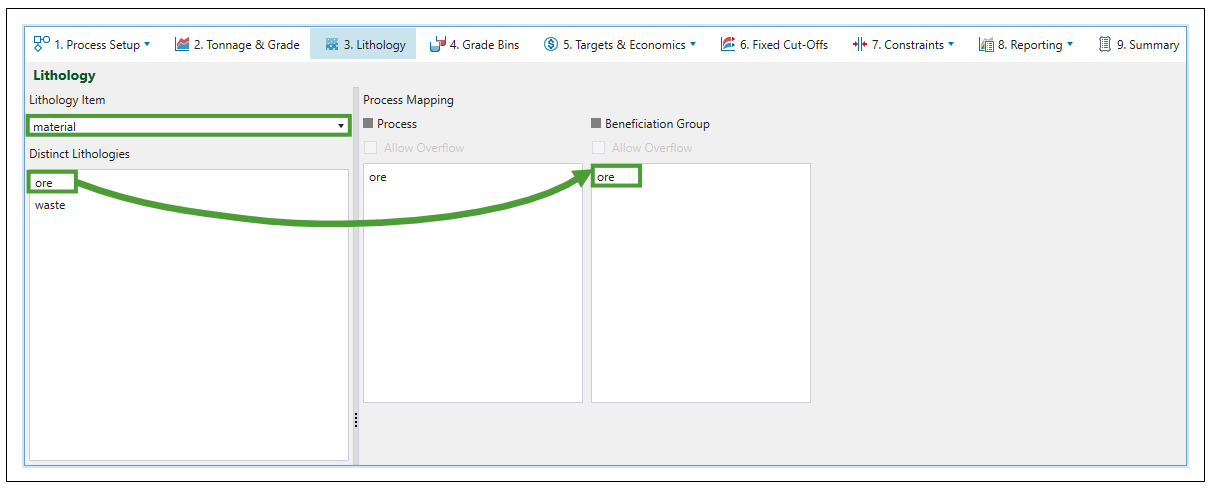

After linking the beneficiation group to the flowchart of your setup, go to the ![]() Lithology tab and specify the material to be sent to it. You can do so by selecting the variable from the Lithology Item drop-down list, and then dragging the required item from the Distinct Lithologies list to the Beneficiation Group column.

Lithology tab and specify the material to be sent to it. You can do so by selecting the variable from the Lithology Item drop-down list, and then dragging the required item from the Distinct Lithologies list to the Beneficiation Group column.

Note: If the beneficiation group has no common lithologies with its connected sources (pits or stockpiles), the pit and stockpile splits will not be reflected in the calendar.

You can also set a fixed process cut-off grade for the whole beneficiation group in the ![]() Fixed Cut-Offs tab.

Fixed Cut-Offs tab.

For more information on defining the target cut-off grade, see Fixed Cut-Offs.

Strategy calculations

| Crusher feed tonnage and grade |

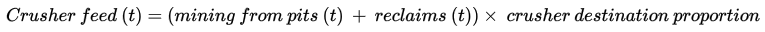

Crusher feed tonnage is calculated according to the following formula:

where Crusher feed grade is the weight average of pit mining and reclaim grades.

You can specify the tonnages and grades in the |

| Bulk Ore Sorting feed tonnage and grade |

Bulk ore sorting feed tonnage is calculated according to the following formula:

where B.O.S. feed grade is the weight average of pit mining and reclaim grades.

You can specify the tonnages and grades in the |

| Mass pull (product and reject streams) |

The proportion of the node’s feed tonnes that is sent to the node’s product stream. The remaining proportion is sent to the reject stream.

You can specify the mass pull value under the Beneficiation Group in the Mass pull is used to calculate product ore tonnes and reject ore tonnes according to the following formulas:

|

| Uplift |

The factor by which the feed grade is increased in the node’s product stream, as a result of reporting higher grade ore to that stream.

The reject stream will have its grade reduced to reflect the lower grade material being reported to that stream.

You can specify the uplift and recovery values under the Beneficiation Group in the The uplift-related formulas that have been implemented in Strategy are as follows:

|

| Revenue |

The revenue that a given process generates is calculated according to the following formula:

You can set the element price and selling cost in the |

,

, indicates the calculated tonnes.

indicates the calculated tonnes.

represents bulk ore sorting, and

represents bulk ore sorting, and